Outside view of the TI Lubbock Plant

|

|

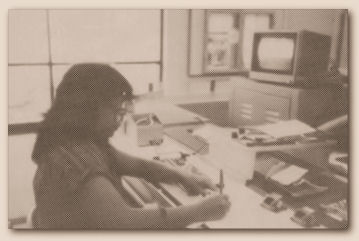

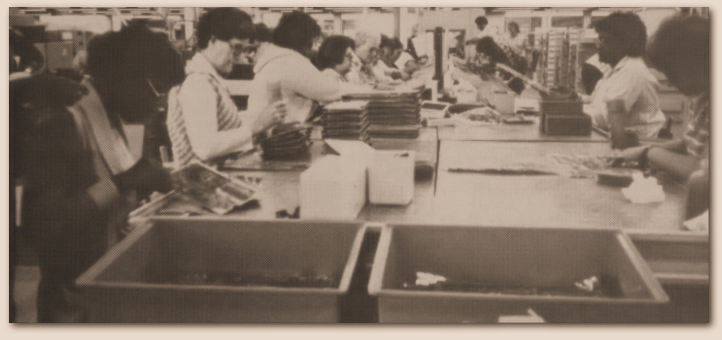

Inside view of the TI Lubbock Plant

|

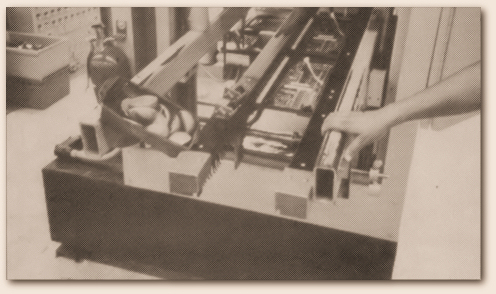

Automated machine inserts components into the motherboards

|

|

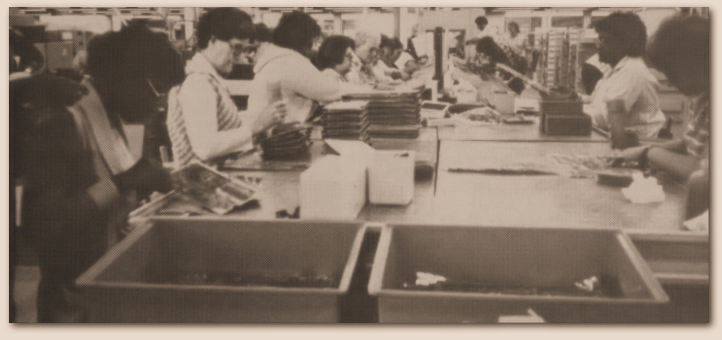

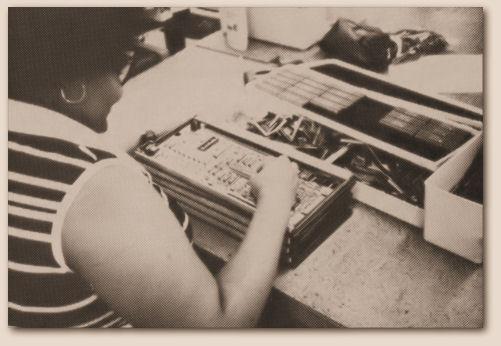

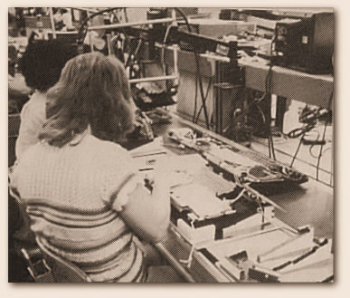

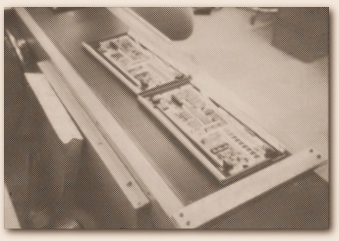

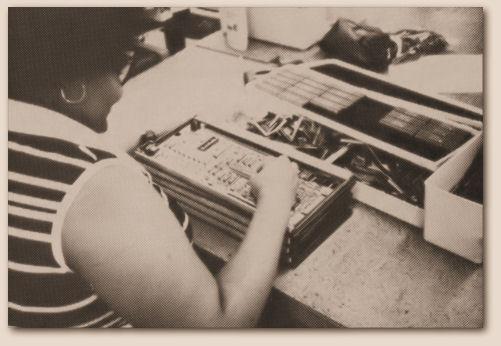

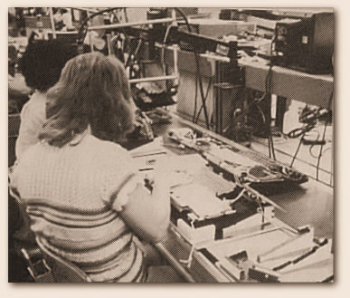

Inserting components the old fashioned way

|

More components being inserted into the power supplies or main board

|

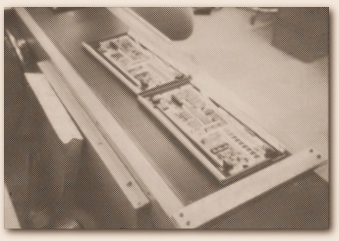

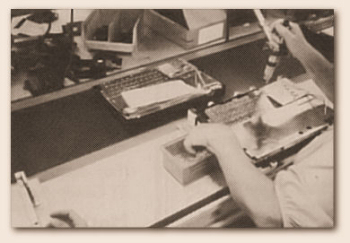

At the end of the line, with all parts inserted and ready for soldering

|

|

Main boards ready for the "flow soldering" machine

|

Power supplies ready for the solder also

|

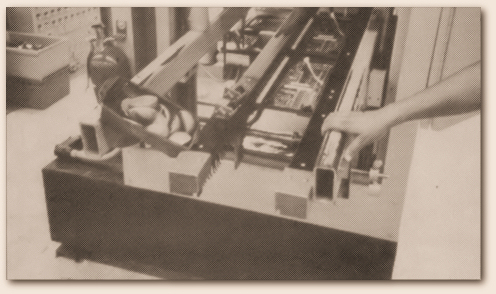

Motherboards placed in the moving rack of the soldering machine

|

Power supplies flowing over a river of molten solder, soldering everything at the same time

|

After the soldering all boards recieve a bath to remove the flux

|

After the bath the boards are dried

|

The larger socket mount chips are inserted, including the TMS9900 CPU

|

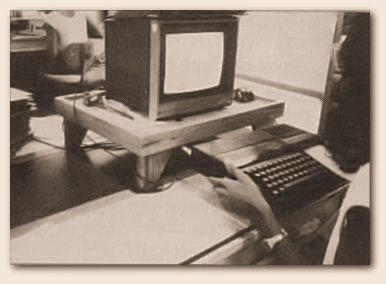

The boards are now powered up for the first time

|

|

All boards connected and tested

|

Metal shielding is applied

|

|

Power supply installed in case

|

Main board is now installed in case

|

|

..followed by the keyboard

|

Console is now subjected to a "drop test"

|

|

Consoles are placed in rack after rack for a three day powered "burn-in"

|

Yet more testing

|

|

Here the consoles keyboards are tested

|

After all the tests, the brushed aluminum trim is applied

|

|

Wrapped, packed, and shipped to a store near you!

|

Pictures from December, 1982 99'er Magazine